Save more than money!

Go refurbished for a greener economy.

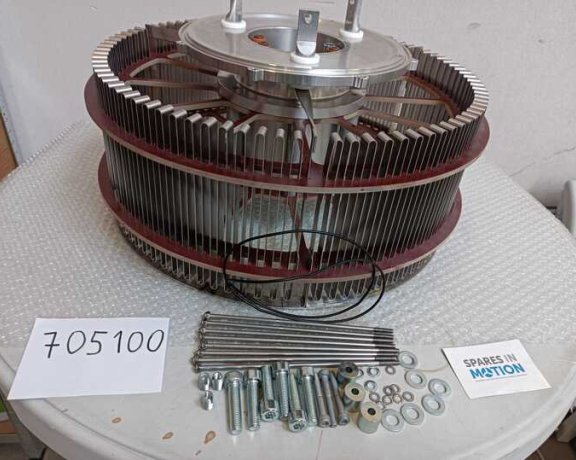

Circular strategies offer a powerful way to extend the life of wind energy assets by refurbishing and repurposing key components—such as gearboxes, yaw systems, control units, generators, slip rings, sensors, power converters, IGBTs, and many other parts —across various conditions. By investing in wind turbine repair and optimization, operators can significantly increase turbine efficiency, reduce maintenance costs, minimize waste, and lower carbon emissions. Read more.

REDUCE COSTS

REDUCE CO2

REDUCE LEAD TIMES

4-Step Refurbishment Process

A value-driven solution

QA/QC

- Supplier development and validation

- Available upgrades or reliability improvements

- Scope of refurbishment/ repair definition

- Obsolescence management (replacement/ alternative)

- Evaluation at no charge

Logistics & Reporting

- Exchange stock available of critical parts

- Door-to-door transport

- Documentation and certificates handling

- Customer Login: Complete track and trace of the repair and exchange loop

- Customer Quarterly Reporting

Warranty

- Extended warranty for refurbished parts (up to 24 months)

- Warranty handling